- 01

01Photography

Unlike traditional woven textiles, Sahari Tsuzure Brocade weaves the weft three-dimensionally, thereby allowing to make not just classical two-dimensional patterns but also depict actual landscapes. At this stage, photographs by professional photographers are taken which will become the basis of the design.

- 02

02Design Sketching

In order for the painters to create obi designs based on the taken photographs, detailed meetings take place over the number of warps and wefts, composition, material, as well as the number of colors to be used in the design.

- 03

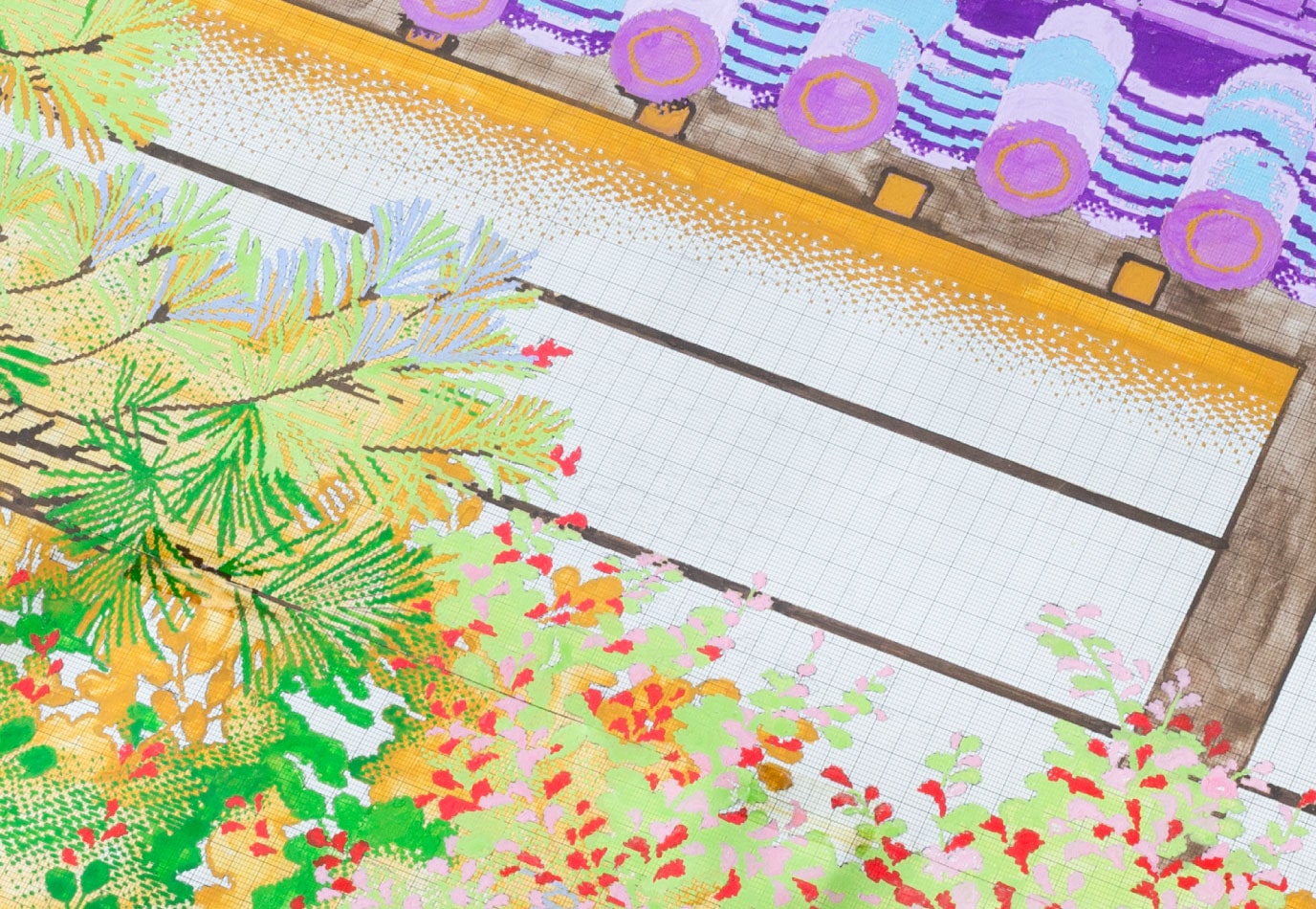

03Design Composition Scheme

As the blueprint for the design, the pattern is magnified and traced onto graph paper. How many colors are used and how it will be woven is painstakingly represented by painting in different colors in order to obtain a complete view of the design.

- 04

04Thread Dyeing (Warp)

At Sahari Tsuzure Brocade, thread dyeing is considered one of the important steps along with the design, and we only use high-quality 5A to 6A threads. In order to carry out a raw dyeing with sericin remaining, only highly-skilled artisans are assigned with the task.

- 05

05Arranging Warp Threads

This process is preparing the length and number of warp threads necessary for weaving. At Sahari Tsuzure Brocade, we use 4600 warp threads.

- 06

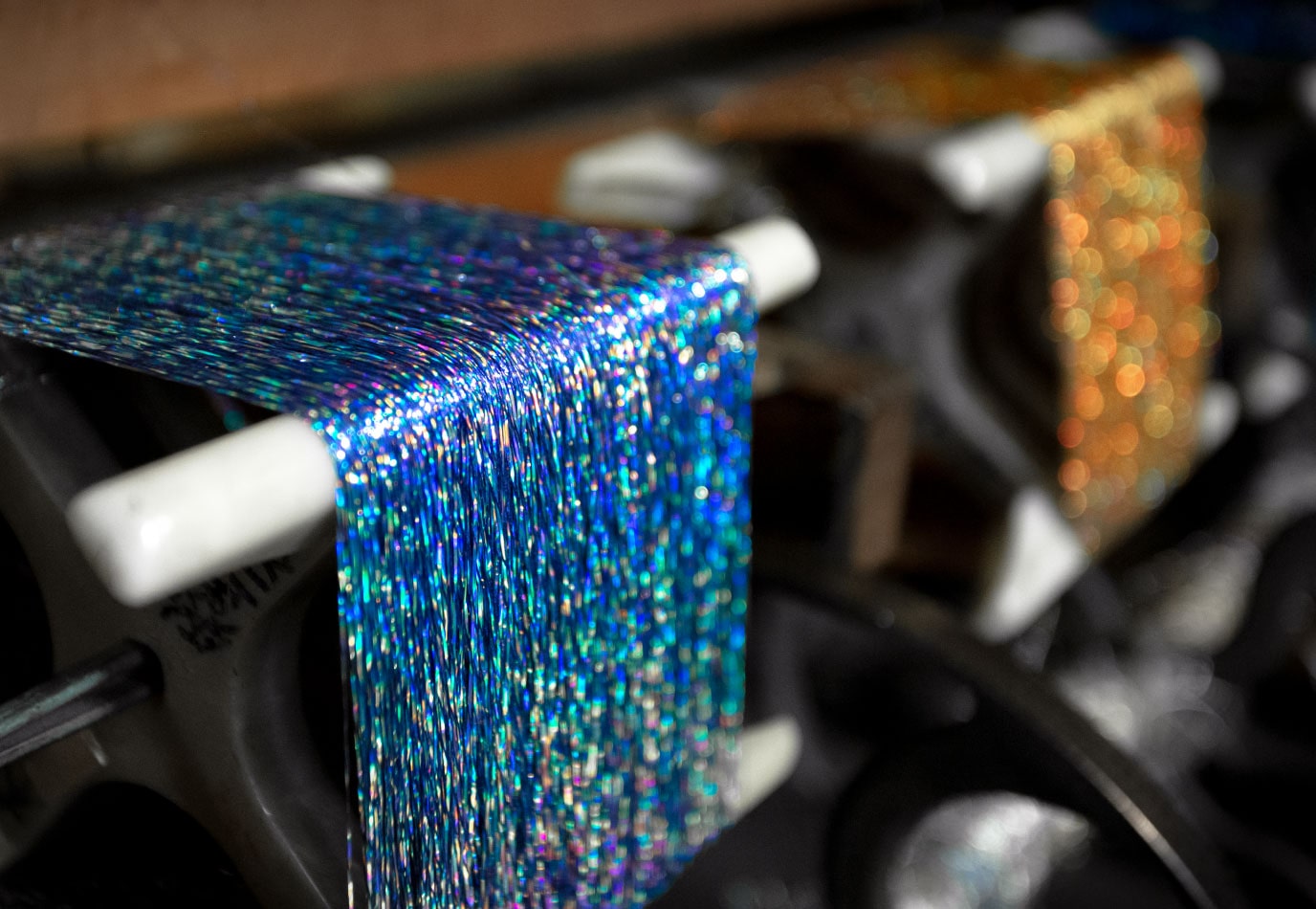

06Spooling Weft Threads

This process involves spooling the gold/silver thread and foil, which will be used in the final product, to make it easier to handle. One feature of the weft used at Sahari Tsuzure Brocade is that no silk thread is used. Instead, we only use custom-made gold/silver thread and foil for our products.

- 07

07Weaving and Inspection

Skilled in our 12 patented techniques in addition to the basic skills for composing tsuzure-ori (figured brocade), kara-ori (Chinese weaving), and tate-nishiki (brocade), only our highly-skilled artisans are assigned the task of making the final product. And because defects can appear depending on the light, our product inspection is carried out in various places under natural lighting, incandescent lamps, as well as indirect lighting to check for composition and coloring.

- 08

08Final Processing

On a one-of-a-kind custom-made basis, the final woven obi is put under close examination to ensure optimal standards, and artisans well-versed with composition and materials steam the obi for final processing.